If a piece of gear quits, you might actually be able to do something about it.

Please Remember:

The opinions expressed are mine only. These opinions do not necessarily reflect anybody else’s opinions. I do not own, operate, manage, or represent any band, venue, or company that I talk about, unless explicitly noted.

Want to use this image for something else? Great! Click it for the link to a high-res or resolution-independent version.

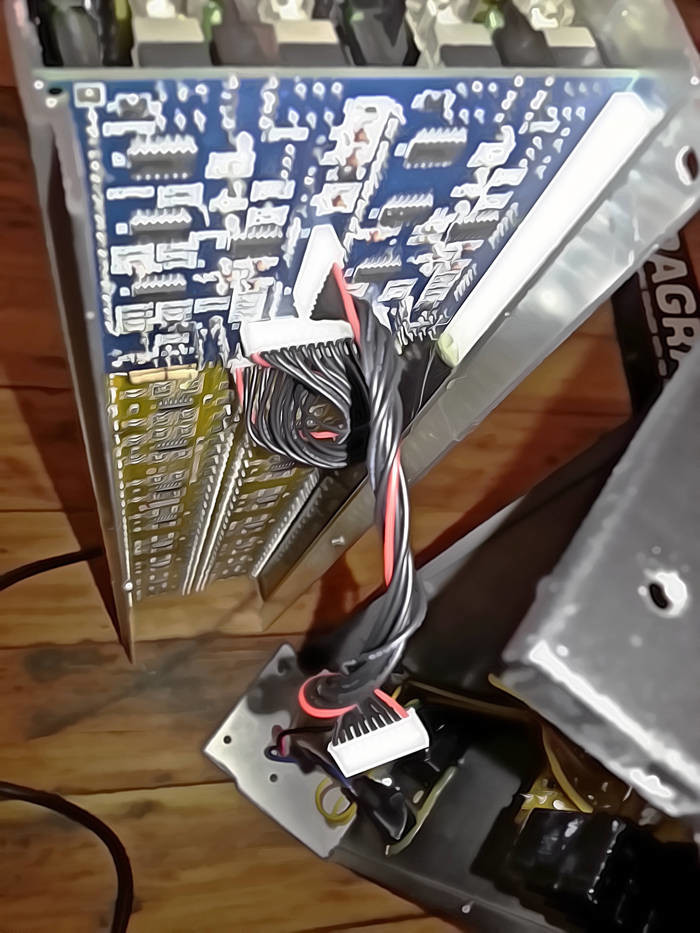

Want to use this image for something else? Great! Click it for the link to a high-res or resolution-independent version.Along with “concert sound,” I also handle audio for my church. Just recently, we had a couple of audio processors decide that they didn’t want to cooperate anymore. One was an FBQ3102 equalizer, and the other was a DEQ2496 (a “not just an EQ but not quite a loudspeaker manager” sort of thing).

We had recently moved to a new space, and the big rack-o-audio had done some bouncing around in the back of a pickup. It had also been bumped down a set of stairs. Whether those were the actual events that precipitated the failures or not, everything together was just a little too much for the units in question. The 3102 stuck channel #1 in a permanent state of bypass, and the DEQ was making all kinds of weird, pink-noisey sounds at its outputs.

After the problems were discovered, I pulled the units from the rack on two separate days. (I won’t get into the full story just now.) On the first day, one of our congregants asked if I was going to send the DEQ off to be repaired. I responded in the negative, saying that I wanted to open it up and have a look first.

I had been inside the DEQ before, and I had a sneaky suspicion that the problem was NOT a failure of some device soldered to one of the boards. My guess was that a ribbon connector had worked loose, and just needed to get reseated. As it turned out the, simple act of pulling the unit out of the rack had gotten the connector to re-settle, and so my manual “pull and reseat” was just for good measure. The DEQ went back in the rack, and has returned to operating as expected.

I can’t remember when I got that DEQ, but I think it was something like seven years ago. Maybe more. They’re great units, and I haven’t found anything similar to them at their price point.

Anyway.

The FBQ was less cooperative. I got it opened up, and tried replugging its internal connections, but that wasn’t the problem. I eventually tried shorting the first pair of pins on the misbehaving channel’s “In/Out” switch – which made the bypass relay fire – but the unit just seemed to get worse and worse. I eventually shrugged my shoulders, replaced the FBQ with an old, faithful, Feedback Destroyer, and that was that.

So, what’s my point here?

The thesis of this article is the title, rendered in imperative form. If you have a piece of gear that seems to be misbehaving, then look inside.

Don’t Be Afraid Of The Wrong Things

It’s easy for us to be intimidated by the thought of pulling the cover off of a misbehaving device. We can’t be sure that we’ll understand anything we see. We won’t know what all the components do. Most of us are NOT electrical engineers. (I surely am not.)

The thing is, though, that not understanding everything about what’s going on inside a piece of gear doesn’t mean there’s nothing at all we can do to service one.

Now, before I go any further, yes, there are some things that you do need to be suitably wary of. Electricity can, and does, end people’s lives. If you’re going to pop open a device that’s giving you trouble, then realize that you’re doing so at your own risk. NOBODY BUT YOU is responsible if you injure or kill yourself, or wreck the unit. Even if you unplug the offending equipment, discharging a capacitor such that you are the path to ground is still a risk.

You have to be careful.

At the same time, being completely terrified of the insides of an audio device just isn’t necessary.

It’s Like Working On A Computer

I mean, at least a few of us have done work inside our computers, right? We’ve swapped out drives, or installed PCI cards, or even assembled a PC from the ground up, right? We don’t know about every little thing soldered to every board, and yet we’ve been able to get a box working. Lots of audio devices these days are assembled in what I would call “computer fashion.” You have various circuit boards that components attach to, a power supply, and various cables, slots, and other connectors that get the different sub-assemblies to exchange voltage. It’s all the same basic principles, it’s just arranged differently.

Yes, it’s possible for things soldered to a board to fail. There was that whole “Capacitor Plague” that Wikipedia describes as having gone on for eight years or so. There are such things as bad solder joints.

But here’s the overall view: A device soldered to a board is much less likely to have a bad connection than a join which relies on, say, friction, to keep things mated. Assuming the solder joint is sound, it’s pretty dang hard to disconnect an individual component from a circuit. You have to act deliberately and apply a sizable amount of heat to separate the part. A ribbon cable, on the other hand, can get loose from something as simple (and not deliberate) as vibration. The same thing can happen with a connection that works like a PCI card.

If you’ve got a piece of gear with a problem, popping the thing open and searching for “manually pullable” wiring assemblies and/ or snap-in components is probably worth your time. Reseating things like ribbon connectors and wiring harnesses helps to eliminate simple connection problems from the equation, and that just might solve the whole thing. There’s a real chance that looking at the easy stuff will save you a costly ship-repair-ship cycle.

So, look inside.